What are Aerated Autoclaved Concrete Blocks? | AAC Vs Solid Blocks | Ecorex

We are extensively surrounded by aerated products in our everyday life; to name a few - bread, Idli and dhokla, etc. The word "Aerated" implies a material that contains lots of microscopic air voids; a porous material. This aerated product is autoclaved - which means that it is heated with steam, and in the case of AAC Blocks it is steamed at 200 degrees centigrade temperature to expedite its strength gain.

The aeration effect in AAC Blocks makes them so lightweight that they float on water. The typical density of AAC blocks is around a mere 650 kg/m3. And this is why Autoclaved Aerated concrete blocks are replacing clay bricks in a big way. The aeration introduced in these blocks during the manufacturing process makes them exemplary. Swedish architect and inventor Dr Johan Axel Eriksson developed these lightweight blocks at the Royal Institute of Technology in the 1920s. One AAC block typically replaces around 8 clay bricks!!

Environmental Protection through the AAC Blocks:

Autoclaved Aerated Concrete (AAC) is an eco-friendly and certified green building material. AAC is known to have a lower environmental impact in all phases of its life cycle, from the manufacturing process through to the disposal of waste.

- Light weight means the dead-load of the building becomes substantially low which in turn means a lesser requirement of reinforcement steel, insignificant concrete sections and a much smaller carbon footprint.

- The high thermal resistivity of the blocks significantly saves lifetime electricity costs by reducing the cooling loads of a building to a degree of 25%.

- Fuel consumption is reduced and there is a saving of 35% as lightweight means more volume can be transported per ton.

- The use of recycled waste like fly ash and gypsum in AAC blocks constitutes almost 70% of its weight resulting in substantially lowering the impact of this product on the environment.

A Quick Comparison Between Red Clay Bricks And AAC Blocks

The Difference In Weight

- For identical sizes, the Weight of One Brick = Weight of Two and Half AAC Blocks. This illustrates that AAC blocks are very very light in weight.

- This also allows for an increase in the size of AAC blocks, about 8 clay bricks in one AAC block.

- This difference in weight results in a huge saving in cement and sand as the number of joints could be reduced up to 6 times.

- This improves the speed of masonry and makes the work much quicker resulting in almost 50% more output in a day.

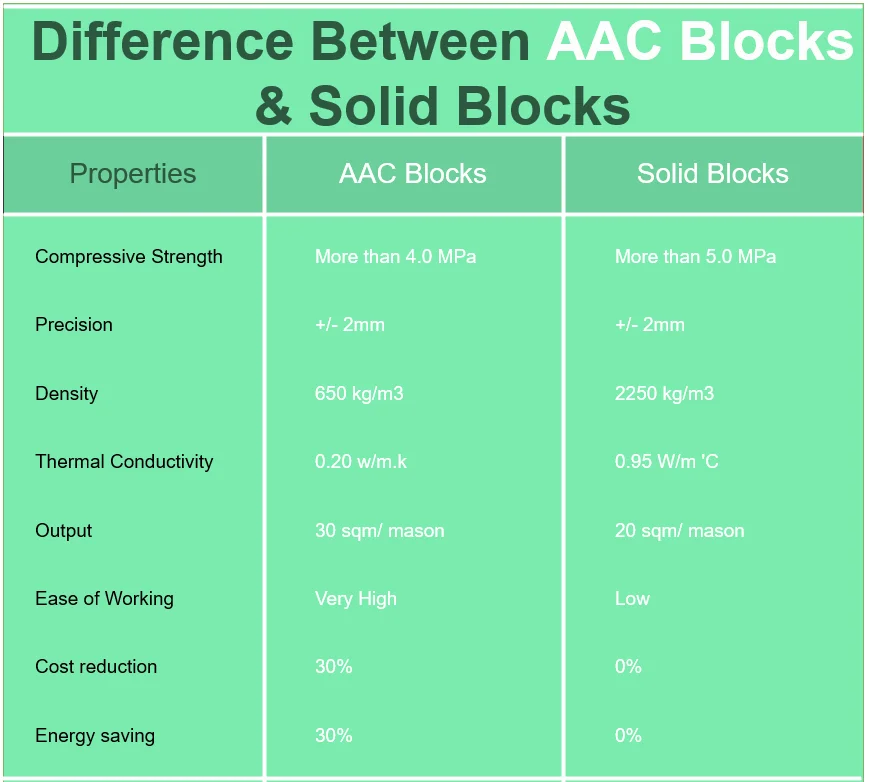

The Difference In Heat Transfer

- AAC blocks have a very low rate of heat transfer compared to burnt clay bricks - about 1/4th only. AAC Blocks = 0.20 W/m'K against 0.81 W/m'K

- This also results in huge savings in the cost of air conditioning by more than 25% in construction sites that use AAC blocks.

The Difference In Water Seepage

- The pores in AAC blocks are not connected to each other which means that they do not allow seepage of water through them by the capillary reaction.

- Whereas, the pores in burnt clay bricks are connected and result in a high rate of seepage of water due to capillary reaction.

The Difference In The Modulus Of Elasticity

- AAC blocks have a low modulus of elasticity compared to burnt clay bricks.

The Difference In Perfection In Size

- AAC blocks have a maximum deviation in height and width of 3mm which ensures a much thinner layer of plaster and thinner joints.

- A thin mortar bed results in substantial savings on sand and cement.

- The block work done using AAC Blocks looks aesthetically pleasing with cleaner joints.

Main Benefits Of Using AAC Blocks

- The key benefits of using AAC Blocks like these mentioned below have paved the way for wider usage of these green building materials.

- Lightweight blocks mean lower reinforcement steel which gives us an economical construction.

- The aeration in these blocks allows for greater fire resistance of up to 4 hours.

- The superior thermal efficiency of these blocks lessens the cooling loads of a building.

- AAC blocks are larger in size which also means faster masonry work, lesser joints and reduced labour costs.

- AAC blocks are environmentally friendly and are known to have a very low environmental impact due to the use of recycled material as its major component.

- AAC blocks provide better and in fact Superior Sound insulation - STC class 45 dB.

- AAC blocks provide better seismic resistance than traditional clay bricks.

Conclusion

Autoclaved Aerated Concrete Blocks were brought to India around 1970 by Siporex (B.G.Shirke) in Pune. Owing to the ever-increasing environmental threats, it revolutionized the construction industry by storm in a big way only after 2008. If we look at metros like Mumbai and Delhi, nearly 70% of the market has been deeply penetrated by AAC blocks. If we look at the second-tier cities across the country, the awareness is spreading rapidly. The shift from traditional clay bricks to AAC Blocks is happening overwhelmingly.

There are many concerns, challenges, and issues that the industry is facing today owing to the growing need and rapid change. A well-formulated ‘IS code’ guiding the quality parameters of AAC blocks: IS 2185 Part III exists to ensure the best quality product.

Keeping in mind today's construction scenario, AAC Blocks are definitely the right fit for the construction needs in the country.

Recent blogs

Thermal Conductivity Of AAC Blocks | U value and R value | ECOREX

AAC blocks were invented for keeping the building thermally insulated and keeping the heat out from the building. Let's dig deep into Thermal Conductivity of AAC Blocks.

Top 5 AAC Block Manufacturers In India

Here is a list of the top 5 AAC block manufacturers in India. Because as a property owner, it is advised to have a working knowledge of different AAC block manufacturers.

Testing AAC Blocks: Compressive Strength | Ecorex

One of the most important characteristics of AAC blocks for the user is their compressive strength. Drying Shrinkage, Dry Density, as well as Compressive Strength, have different test procedures. Let's find out more together.

Testing AAC Blocks: Dry Density | Ecorex

Most of the popularity that AAC blocks have gained over the years is due to their unique characteristic of being lightweight. This is checked with the help of a dry density test.