Code IS 2185 - Benchmarking AAC Blocks In India | Ecorex

What is IS Code?

IS Codes or Indian Standard Codes exist in India to verify and authorize every aspect of civil engineering in the country. Indian standard codes are a list of codes used by civil engineers in India for the design and analysis of civil engineering structures such as buildings, dams, roads, railways, airports and others. These codes are used on different occasions based on the nature of work and engineering projects. AAC Block or Block Jointing Mortar is no different in that aspect.

Why IS codes are used?

IS Codes provide standard requirements or specifications that prescribe other indicators for various materials used in the manufacture of concrete structures. These

codes ensure that various requirements like strength and serviceability are met in design. It is a code of practice for the design of General Construction in steel-code and practices. From professional engineers to a student, everyone involved in civil work utilizes these codes at various points in their life.

How many types of IS codes are there?

As per the latest modification in the list, a total of 203 types of IS codes are available in India which cover every characteristic of civil engineering in the country.

The code IS 2185: Part 3

The code IS 2185: Part 3 gives important properties and permissible values for AAC (Aerated Autoclaved Concrete) Blocks.

These blocks are extremely lightweight and have certain unique properties. IS code 2185: Part 3 specifies these properties and also gives permissible values to these properties.

What Are the Important Concepts to Understand in this Code?

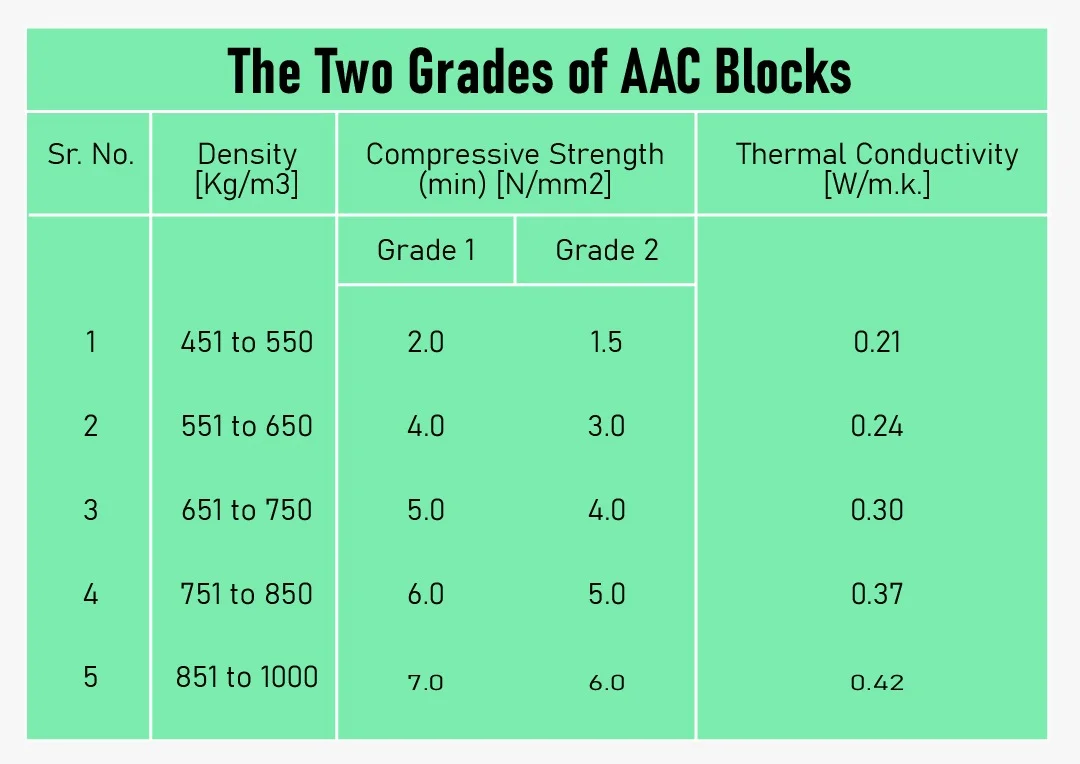

1. The Grades of the Blocks

The code has distinguished the blocks into two Grades:

Grade One for high-strength blocks

Grade Two for low-strength blocks

The two grades differ not only in their strength but also in the drying shrinkage values.

2. Acceptable Limits of the five properties

The code has specified five properties for AAC blocks which are the most important part of this code. Understanding these five properties would let one master 90% of the code.

What does the above table tell us?

- AAC blocks can be used for constructions that are as light as 451 kg/m3 to as heavy as 1000 kg/m3.

- On testing the strength of a block, it must match its corresponding density group. For example, 2 N/mm2 blocks are acceptable given the density is in the range of 451 to 550 kg/m3.

- The heavier the block, the higher the value of thermal conductivity.

The most popular density group in India is the density range of 551 to 650 kg/m3 which has a thermal conductivity value of a maximum of 0.24 W/ m.k.

Recent blogs

Thermal Conductivity Of AAC Blocks | U value and R value | ECOREX

AAC blocks were invented for keeping the building thermally insulated and keeping the heat out from the building. Let's dig deep into Thermal Conductivity of AAC Blocks.

Top 5 AAC Block Manufacturers In India

Here is a list of the top 5 AAC block manufacturers in India. Because as a property owner, it is advised to have a working knowledge of different AAC block manufacturers.

Testing AAC Blocks: Compressive Strength | Ecorex

One of the most important characteristics of AAC blocks for the user is their compressive strength. Drying Shrinkage, Dry Density, as well as Compressive Strength, have different test procedures. Let's find out more together.

Testing AAC Blocks: Dry Density | Ecorex

Most of the popularity that AAC blocks have gained over the years is due to their unique characteristic of being lightweight. This is checked with the help of a dry density test.